At a glance

Process engineering calculation with the help of various calculation programs

- In-house calculation software. Based on the VDI heat atlas, verified by test stand measurements

- Design of surface/vacuum condensers according to HEI

- Lauterbach process technology

Engineering, constructive design

- 3-D constructions

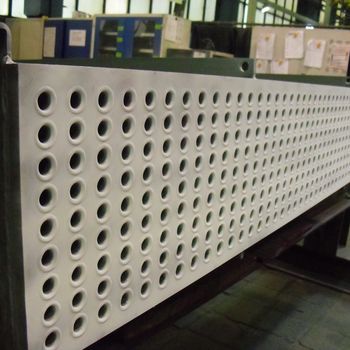

- Project-related designs of pressure vessels, heat exchangers and support structures in close cooperation with our customers

- Designs according to the specifications of our internationally operating customers with their assigned engineering offices as well as the prescribed regulations PED, AD-2000 information sheets, EN 13445, ASME, TEMA, API etc.

- Strength calculations of equipment according to AD-2000, EN13445, ASME VIII/1 taking into account additional external loads.

- Creation of order documentation that conforms to regulations and specifications

Supply of components and accessories

- Filling and testing equipment, temperature sleeves

- Separator tanks/skids

- Pulsation dampers

- Regreasing container

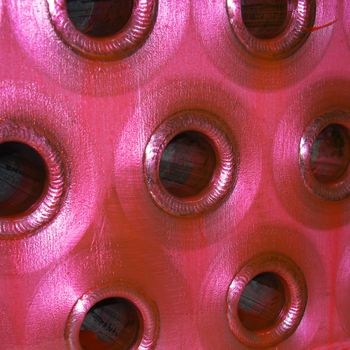

- Production of components with special coatings (thick coatings, rubber coatings, Rilsan coatings, PTFE coatings)

- Filters including spare parts

- Valves, gate valves, dirt traps, motors, pumps, other components for oil plants

- Tube bundle installation and removal devices

- Pressure test devices / equipment

- Cleaning modules / separators for oil systems

- Sacrificial anodes

- Special constructions: Flushing equipment

- Weather protection covers / canopies

- Control cabinets

Projectmanagement

- Preparation of production flow plan via MS-Project

- Proactive forwarding of monthly progress reports with pictures of current status of manufacturing

- Weekly project meetings in order to safe contractualdelivery dates and quality standards

Production

- Welding of special materials (13CrMO 4-5; Inconel, Monel, Titanium etc.)

- Welding support for hydraulic cylinder production

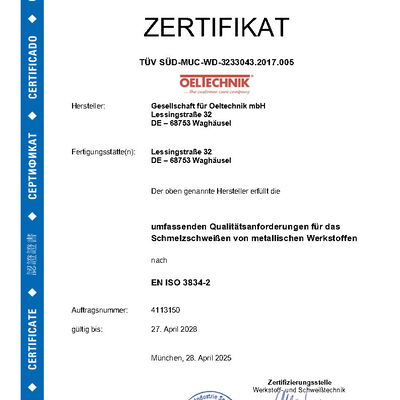

Quality assurance

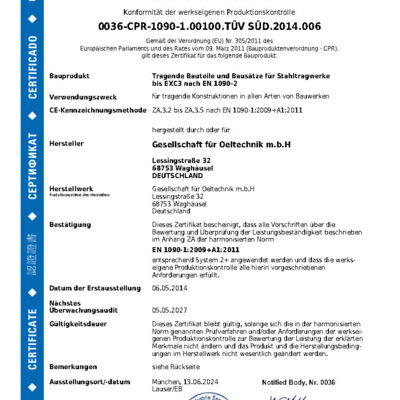

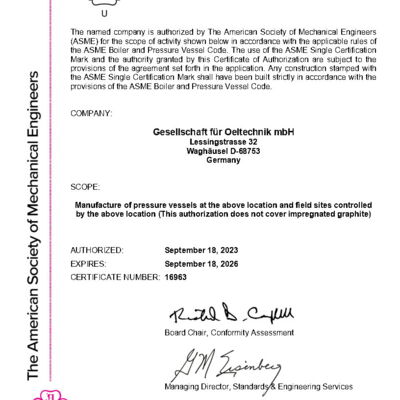

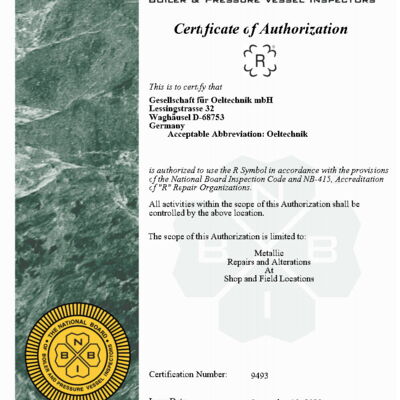

- According to requirements of national and international regulations (e.g. AD 2000 information sheets, DIN EN 13445, ASME Sec VIII Div. 1, WHG, DIN EN 1090 Exc. 3, TRBS 1203, EAC 010/2011 and 032/2013, etc.) and specific customer requirements

- Quality control / monitoring

Assembly & service

- international experienced, in-house service team with longterm experience in assembling, service and repairing of products, inside and outside of OELTECHNIK group

- more: www.oeltechnik-service.com

Quality management

Whether chemical and petrochemical industry or energy and marine technology, we have the necessary approvals as well as the corresponding expertise to realize the requirements for our customers accordingly.

A corresponding qualified and complete digital documentation according to the different regulations as well as customer requirements, is standard for us.

Non-destructive testing methods (NDT)

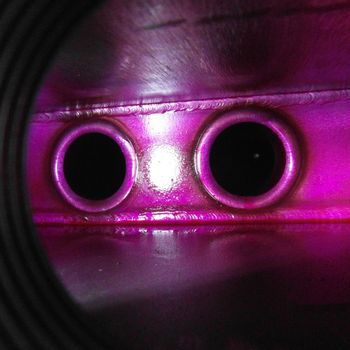

In order to ensure a consistently high quality of our products, they are checked by non-destructive testing methods (NDT).

The following procedures are applied:

- Radiographic testing (RT)

- Ultrasonic testing (UT)

- Magnetic particle inspection (MT)

- Dye penetrant testing (PT)

- Visual inspection (VT)

Special test procedures such as TOFD, acoustic emission measurement and helium leak test can also be carried out on request.

Our personnel is certified and qualified according to DIN EN 9712 Level 2 as well as Level 3 and according to SN-T-C-1A Level II, as well as Level III.

Our department is equipped with all the necessary equipment, including gamma workstations SE-75 and Ir-192, direct beam tubes (200KeV), mass spectrometers, endoscopes, and much more. These tests are performed almost exclusively with our own equipment and testing personnel. Endoscopes and mass spectrometers for He density testing are also available, as is the testing technology for performing quality monitoring of coatings in accordance with DIN EN ISO 12944.